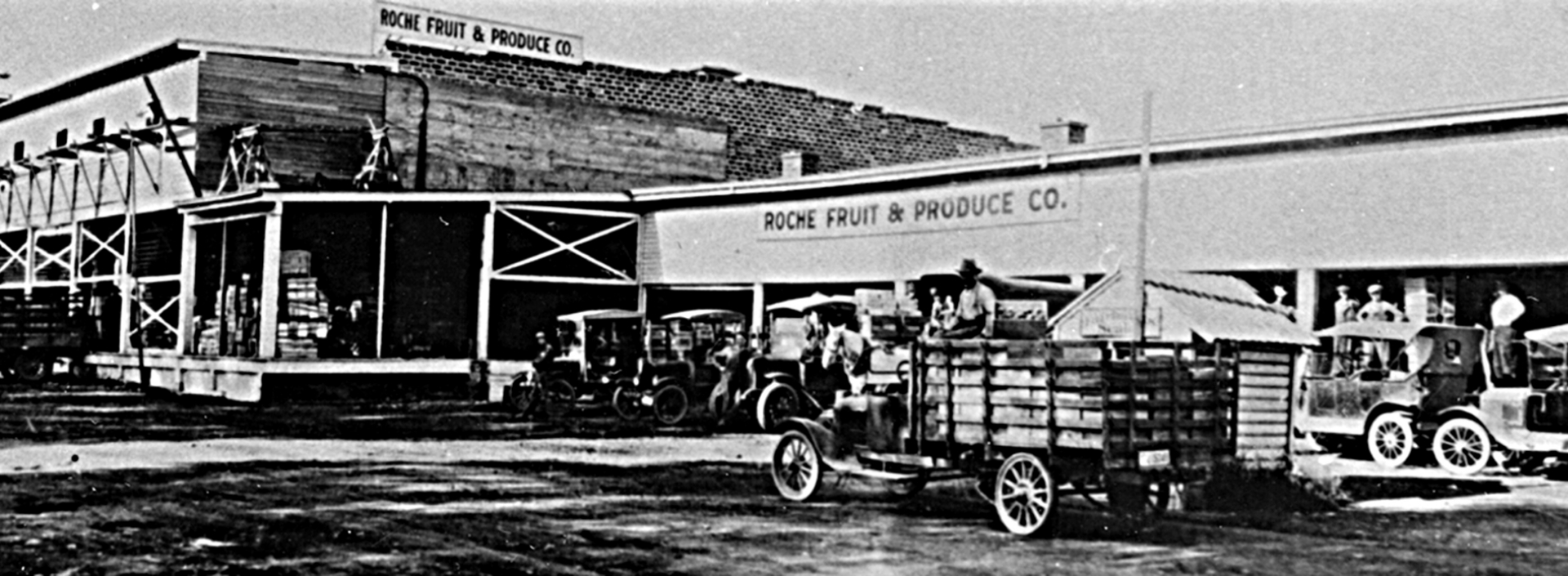

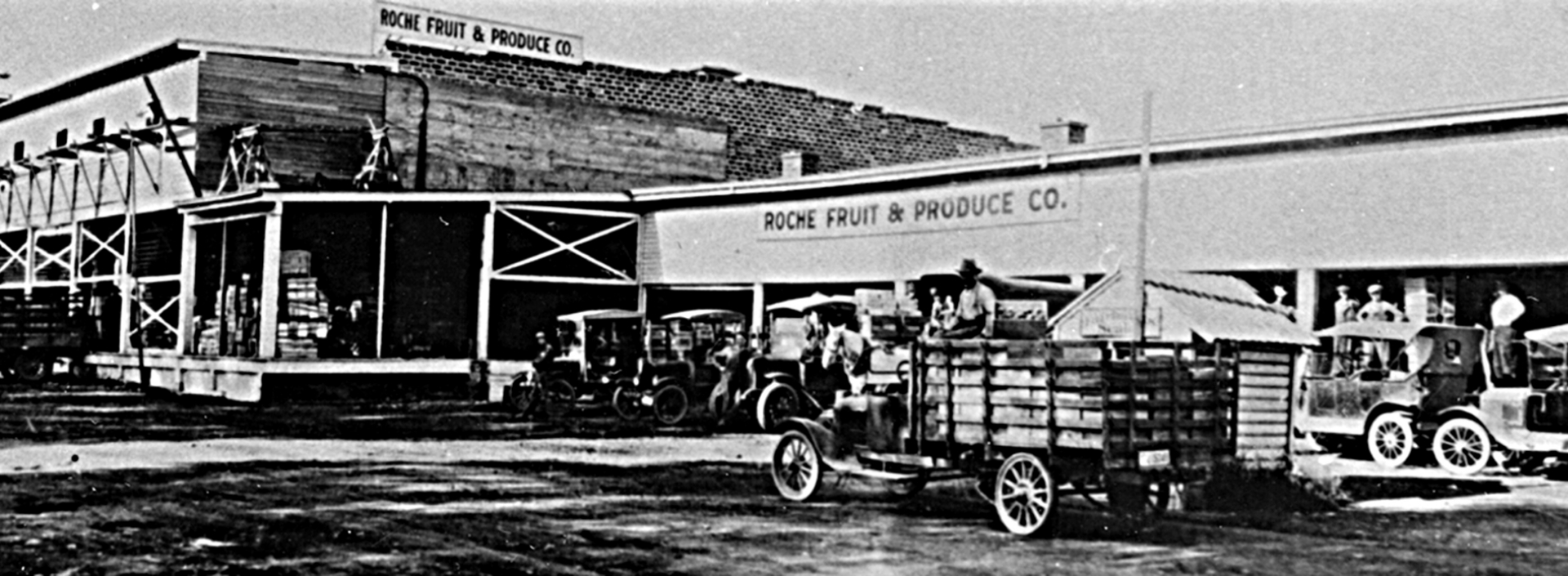

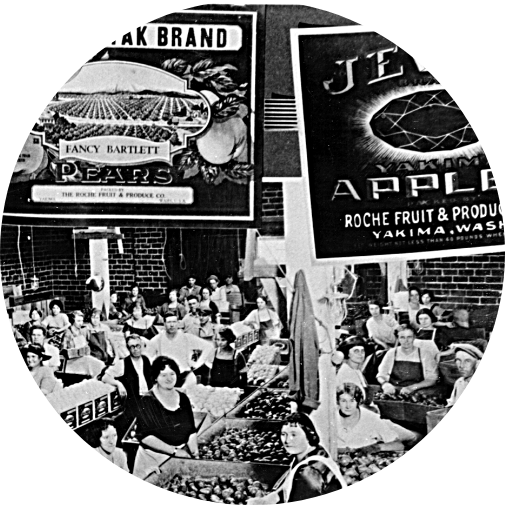

With four generations of experience, stringent compliance to food and worker safety standards, and ongoing investments in state-of-the-art technologies, Roche Fruit provides the best apples straight from Washington State.

As a grower-based apple packaging facility, we own and farm over 2,000 acres and partner with many growers across the region. We guarantee the quality of our apples—from the earth to our consumers’ hands all across the globe.

Our competitive processes and technologies combined with our specialized experience put us at the forefront of apple growing, storing, processing, and shipping. From high-speed infrared sorting capabilities to automated palletizing, we’ve embraced the future while staying true to our homegrown roots.

Roche Fruit is poised to lead the industry, continually striving to make improvements through careful consideration of our natural resources and impact on the environment. In 2020, approximately 180 tons of waste cardboard and paper products were recaptured and transported to a recycling center to be used in other packaging products. We invest regularly to streamline processes, reduce energy, and conserve resources—from V-trellis plantings and farming best practices to modernized refrigeration, sanitizing, and more.

Ongoing Sustainability Initiatives:

Farm-level Innovation

The V-Trellis—Better for Earth, Workers, & Consumers: Roche Fruit is moving future farm plantings to V-trellis and other high density systems, which maximizes harvest potentials by increased yields (bins per acre), maximizes sunlight potential, reduces water use with drip irrigation and soil moisture monitoring, reduces fertilizer and chemical use, increases harvesting speeds by allowing worker platforms to travel unobstructed, and minimizes employee injury from ladders and the need for heavy picking bags.

Ultimately, the V-trellis method is one step closer to a harmonized system between humans and the environment.

Mentorship: We’re committed to cultivating our leaders from within the organization and have developed an open, available, yet rigorous, On-the-Job Training and Mentorship Program. Through building relationships, Roche Fruit creates opportunities for growth and advancement.

Education: From the orchard to packing, education is key to the success of our workers. That’s why we’ve developed an open, available, yet rigorous, On-the-Job Training Program, and scholarship opportunities each year. We’ve also invested in digital training platforms to advance industry standards, providing on-demand education and safety training at every location.

Some areas of focus include:

Scholarships are awarded each year, through the Washington Apple Education Fund, to employees, or their family members. We encourage all employees to work towards their educational goals and we are proud to provide financial support.

Safety: From safe lifting to environmental protection training, Roche Fruit has invested in safety projects to ensure a safe workplace:

We pride ourselves on our intensive methods for a safe, efficient, sustainable process that ensures Washington apples remain the best in the world. Learn more about our certifications and standards here.